Our Services

Life Cycle Assessment (LCA)

Providing LCA services for low-carbon energy and industrial applications including CO2 capture and storage (CCS), direct air capture (DAC), low-carbon fuels, renewable energy, and industrial processes.

Sustainable planning through LCA

Life cycle assessment (LCA) addresses a range of low-carbon applications, including CO2 capture and storage (CCS), direct air capture (DAC), low-carbon fuels, renewable energy, and industrial processes. These assessments are conducted by a cross-functional team of engineers, economists, and modelers, providing detailed insights into the potential environmental and human health impact of projects.

LCA identifies areas of opportunity for reducing the environmental impact of any product or process. Projects supported include net-negative and low-carbon power (e.g., Fossil power plants, biomass gasification), net-negative and low-carbon fuels (ex. sustainable aviation fuels (SAF), hydrogen), CO2 storage and transport, building material production (e.g., cement, lime, concrete), and more. Additionally, we provide support for 45Q, 45V, and government FOA LCA preparation.

Our Process

Adhering to the highest industry standards, LCAs quantify the environmental and human health impacts of products, services, and systems.

Goal and Scope Definition & Life Cycle Inventory Analysis (LCI)

- Clearly define the purpose of the LCA.

- Specify the system boundaries to include in the LCA, considering all stages from raw material extraction, manufacturing, use, and disposal (cradle-to-grave), or a subset of these stages.

- Specify the methodology used to collect and evaluate data, such as data quality and allocation choices.

- Collect data that quantifies the inputs and outputs of the system being studied. This includes raw materials, energy use, emissions to air, water, and land, and other environmental aspects.

Life Cycle Impact Assessment (LCIA)

- Identify and assess the magnitude and significance of the potential environmental impacts of the system.

- Select appropriate impact categories (e.g., global warming potential, acidification, eutrophication) and indicators that reflect the goal and scope of the study.

- Apply characterization models that quantify the contributions of different emissions and resource uses to each impact category.

Life Cycle Interpretation

- Analyze the results to identify significant issues based on the LCI and LCIA phases.

- Evaluate the study considering completeness, sensitivity, and consistency checks.

- Provide conclusions, limitations, and recommendations that are consistent with the goal and scope of the study.

Reporting, Critical Review, and Continuous Improvement

- Report the results, methods, and interpretations transparently and completely.

- Depending on the intended application of the LCA, a critical review by an external expert or panel may be required to ensure compliance with ISO 14040 and 14044.

- Use the insights gained from the LCA to inform decisions and drive improvements in product development, strategic planning, policy-making, and other applications.

We analyze critical environmental metrics to offer a holistic view of energy systems

Carbon Intensity or Global Warming Potential (GWP): Measures the contribution of each system to climate change.

Greenhouse Gas (GHG) Emission Reporting: Evaluates the contribution of systems to climate change by quantifying greenhouse gas (GHG) emissions throughout the entire lifecycle of a product or process.

Water Use: Measures the impact of water consumption on resources and ecosystems.

Energy Use: Assesses total energy inputs required across a lifecycle, identifying areas for improvement.

Land Use: Considers impacts on land transformation and habitat disruption.

Other Ecosystem, Air, and Health Impacts: This can include contributions to acidification, eutrophication, ozone depletion, and other eco-toxicity and human toxicity impacts.

FAQs

Learn more about Life Cycle Assessment (LCA) and how it can benefit your organization.

What is LCA?

Life cycle assessment, or “LCA”, calculates the impact that a product, service, or system has on the environment, resource availability, and/or human health. These impacts are calculated over defined life cycle stages, such as from gate-to-gate, cradle-to-gate, or cradle-to-grave.

Why is LCA important?

An LCA helps individuals to consider the broader impacts of a product, service, or system beyond just what is produced or performed. By assessing broader impacts, product and process design can be adjusted to minimize impacts on human health, local environments, and resources that might be scarce or in high demand. LCA also helps to identify “hot spots” or key components of a product, service, or system design that have the highest impacts, allowing individuals to evaluate other alternatives that might reduce impacts.

How is LCA conducted?

An LCA is comprised of four major steps: Goal and scope definition, Inventory analysis, Impact assessment, and Interpretation. First, the goal and scope of the LCA is defined, which includes explicitly determining the goal of the LCA and the life cycle steps that will be analyzed. During inventory analysis, data needed for the LCA is collected and data quality is assessed. This data is then normalized and converted to environmental, human health, and resource impacts in the impact assessment stage. After each step, the interpretation step is performed, wherein the LCA process is reviewed, verified, and refined.

What are the benefits of LCA?

The results from an LCA can help businesses, engineers, and the public to fully grasp all the potential impacts of a product, service, or system. Often there are externalities associated with certain design decisions that are unclear without an LCA, such as the potential human health impact of choosing to use on chemical over another in a chemical manufacturing process. LCA helps those responsible to carefully consider and minimize the impact of their decisions, and better account for these sometimes forgotten externalities.

How can I get started with LCA?

Starting an LCA involves understanding its four key phases—goal and scope definition, inventory analysis, impact assessment, and interpretation—and familiarizing yourself with methods for classifying impacts. Following ISO 14040 and 14044 standards ensures the assessment is thorough and compliant. Various LCA software options are available to support this work, such as paid tools like SimaPro and free alternatives like OpenLCA. Consulting experienced professionals or individuals with LCA expertise can also help guide the process effectively.

Our Team

Specialists in Lifecycle Assesment

Tracey Ziev

Director of Project Engineering

Tracey has a background in mechanical engineering and public policy, with experience in nuclear power and electricity generation.

She has experience in nuclear power and electricity generation, and is leading several projects related to developing CO2 pipelines.

Kat Sale

Research Engineer

Kat is a chemical engineer who focuses on life cycle analysis and techno-economic assessment.

She supports projects by better characterizing point-source emissions and direct-air carbon capture technology.

Marcos Miranda

Research Scientist

Marcos is an environmental engineer with expertise in carbon capture, storage, and sustainable energy solutions. His experience spans research and implementation projects focused on decarbonization and the energy industry.

He contributes to Carbon Solutions’ projects by applying advanced modeling tools and software to support carbon capture, storage, and emissions reduction efforts.

Andrew Harrison

Research Scientist

Andrew is a chemical engineer with a background in energy modeling, forecasting, and utility regulation.

He explores how social, health, and physical data can assist in equitably implementing decarbonization technologies.

Information Hub

Our Lifecycle Assessment Projects

We have LCA experience in a wide variety of industries, locations, and contexts.

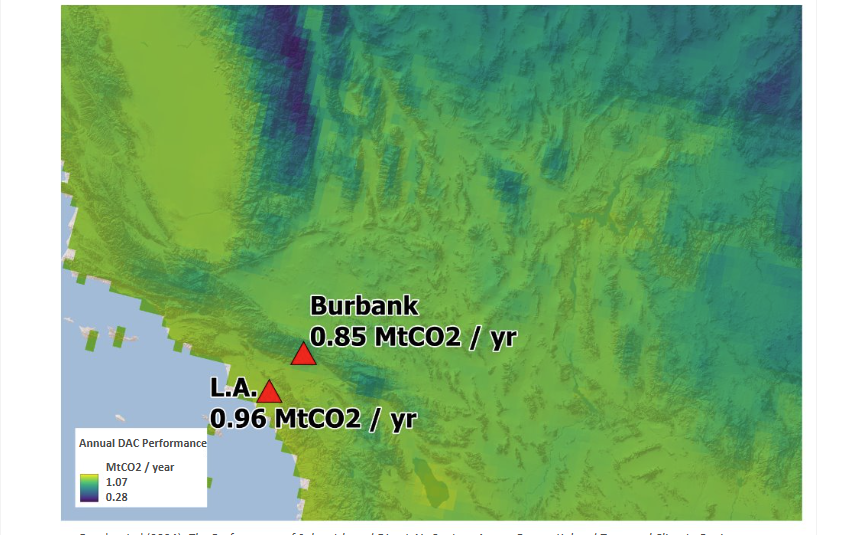

The Negative CO₂ Emission Transition Roadmap (NECTAR) was developed as a decision support tool to facilitate the strategic deployment of Direct Air Capture with Carbon Storage (DACCS) and other carbon dioxide removal (CDR) technologies.

Client testimonials

Collaborating with the very knowledgeable Carbon Solutions team members was a pleasure. They have been very responsive and helpful in assisting with use of their state-of-the-art modeling tools for CO2 pipeline sizing, costing, and routing, as well as with preliminary suitability screening of potential CO2 storage reservoirs.

Arya Gunawan, Cecelia Isaac, and Eric Larson

Get in Touch

Have a question? Need more information? Contact us today.